Key Project Details That Drive Better RFP Responses for Water Slide Refurbishment Projects

For most aquatic facilities, spring refurbishment is the last major hurdle before opening day. Slides have to look right, ride right, and hold up through the season, all while inspections, staffing, and weather are already working against the calendar.

When waterslide resurfacing or steel coating work is bid for a May opening, the RFP process sets the tone for everything that follows. The way a contractor evaluates the slide, asks questions, and plans their work often matters more than who comes in as the lowest bidder. Those early decisions influence whether a project opens clean or becomes a source of ongoing maintenance during the season. While proposals may look similar on paper, the real differences show up later in execution. To understand what allows refurbishment projects to run smoothly and deliver consistent results, it helps to look at the information that drives how work is planned and performed in the field.

The sections below highlight the areas experienced aquatic contractors focus on early, because these details influence how work is coordinated, how surfaces perform once slides are back in service, and how they are maintained season after season.

1. Slide Geometry, Ride Path, and Coverage Reality

Slide measurements are more than a cost-per-square-foot calculation. Total ride path length, entry and exit tub depth, arc lines, circumference, and the number of seams all affect material usage, coverage strategy, and surface preparation efficiency.

Without accurate measurements, some contractors default to coating only the ride path of the slide interior, substituting paint products where gelcoat should be applied, or compressing preparation timelines. These approaches may look acceptable initially, but they often show up later as uneven wear, visible transition lines, or changes in ride feel.

These details matter because they directly influence:

How surface preparation is performed, including sanding grit selection and feathering

Whether a true 360-degree interior gelcoat application is achievable on enclosed slides

The depth and extent of seam removal required

How consistent the ride surface feels once the slide is back in operation and how it holds up visually over multiple seasons

When these factors are understood early, bids are more likely to reflect the correct application method and realistic execution timelines.

2. Existing Conditions and Coating History

Most slides being refurbished today are not seeing their first coating. Previous gelcoat applications, exterior paint systems, and past repairs all influence surface preparation requirements and how new coating systems will perform over time.

Conditions such as UV-damaged topcoats, flaking paint layers, improperly cured gelcoat, and temporary patch repairs are common in the field. When these issues are not identified and addressed prior to refurbishment, they are often the underlying cause of premature coating failure.

Understanding existing conditions allows contractors to properly account for:

Prior gelcoat thickness, cure condition, or existing exterior coating systems

Areas of delamination, chipping, or cracking that may require fiberglass repair

The depth and intensity of surface preparation needed to achieve proper adhesion

When coating history or surface condition is assumed rather than evaluated, scope adjustments often occur once work begins. Addressing these realities early supports more accurate bids, reduces the likelihood of change orders, and helps prevent avoidable maintenance issues after reopening.

3. RAL Color Choice and Finish Expectations

The color of your waterslides is more than an aesthetic decision. Interior and exterior color selections influence coverage requirements, preparation intensity, and sequencing, particularly within a tight execution window and fixed budget.

Certain RAL colors, such as Signal White, typically perform better for interior gelcoat applications when consistency and long-term appearance are priorities. Exterior paint systems, on the other hand, may require different application approaches depending on whether colors are being matched or changed.

Contractors generally need clarity on:

Whether interior gelcoat colors are being maintained or changed

Whether exterior finishes are being refreshed or re-themed

Whether selected colors realistically allow for single-coat or multi-coat coverage

Some facilities also use refurbishment as an opportunity to align slide colors with new construction or updated park theming. When color intent is defined early, bids are more accurate and finishes are more consistent once work is complete.

4. Access, Work Windows, and Site Coordination

Access planning and site coordination play a major role in how efficiently refurbishment work progresses. Lift access points, equipment staging areas, ground protection requirements, and work hour expectations all shape how work is sequenced and executed in the field.

Spring refurbishment often overlaps with other trades and pre-opening activity. Knowing whether additional contractors will be working nearby helps crews plan around shared spaces and avoid conflicts that slow production. On constrained decks or heavily landscaped sites, access limitations can dictate how and when coatings are applied. When these conditions are understood early, contractors can select appropriate lift sizes and staging locations that support steady, uninterrupted work.

Work window expectations also factor into execution. Some projects benefit from flexible access that allows crews to adjust around weather, temperature swings, and cure times. Others require stricter schedules that demand more deliberate planning to maintain surface quality and consistency.

In summary, spring slide refurbishment is about more than finishing work before opening day. It is about setting up a season where slides perform as expected, surfaces hold up under use, and operators are not chasing avoidable issues once guests are in the park.

The strongest projects begin with clear communication early, including an understanding of how proposals are intended to be evaluated. Some facilities prefer strict adherence to a defined scope, while others welcome contractor recommendations or alternates based on field experience and site conditions. When that expectation is clear, contractors can align their approach with the park’s goals and operating realities.

Ultimately, successful refurbishments come from teams that understand how slides perform in the field, how coating systems behave over time, and how to work within the realities of an aquatic opening schedule. When those factors are considered early, refurbishment work is more predictable, finishes last longer, and opening day arrives with confidence rather than uncertainty.

If your facility is planning slide refurbishment this season, RAW Custom Coatings is available to evaluate existing conditions, review scope, and provide recommendations based on real-world aquatic experience before work begins.

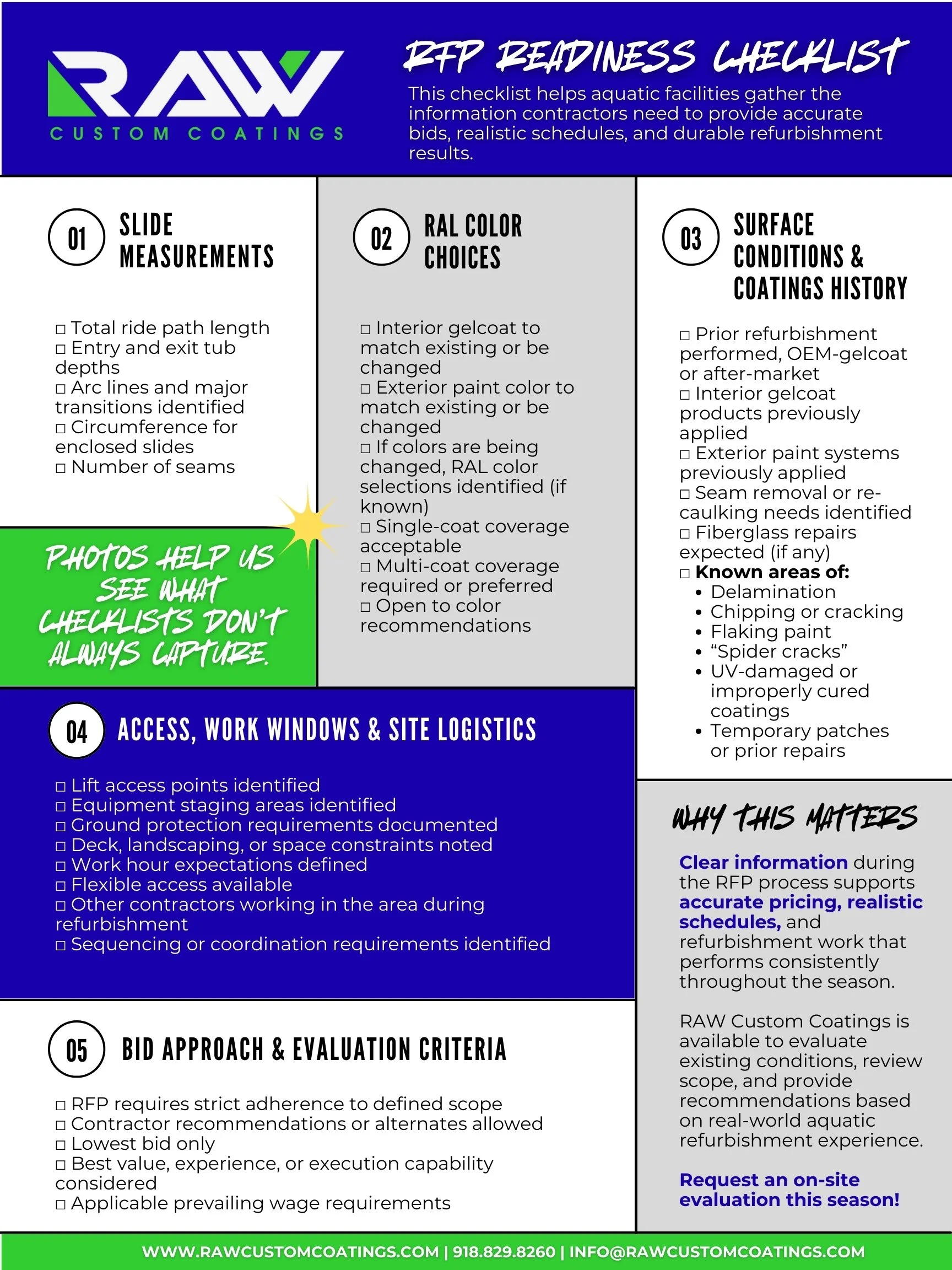

Use RAW’s RFP Checklist

A practical guide to help aquatic facilities gather the information contractors need to deliver accurate bids and durable results.